Why us?

Our Plants

The range of plants that we have to offer you is exceptional. We understand that not everyone needs a full trolley of, say, Heathers in a single delivery. You want two trays of 9cm heathers? Not a problem … with all our other products available, we can quickly complete your order from one supplier, which you know means less paperwork and more time for you to look after your customers, staff and plants. The vast majority of our propagation material comes from well established mother plants here on our site.

This enables us to manage these plants to optimise the material available (depending on whether we wish to produce scions for grafting or to produce cuttings), ensure that they are disease free and, as importantly, true to name. Included in our site are approximately six acres of open ground in which we not only grow our rootstock stems for top-grafting, but a proportion of our container grown stock spend two years in this ground as well. These include Hamamelis, Viburnum, Magnolia and some Thuja.

This enables us to manage these plants to optimise the material available (depending on whether we wish to produce scions for grafting or to produce cuttings), ensure that they are disease free and, as importantly, true to name. Included in our site are approximately six acres of open ground in which we not only grow our rootstock stems for top-grafting, but a proportion of our container grown stock spend two years in this ground as well. These include Hamamelis, Viburnum, Magnolia and some Thuja.

These should not be confused with containerized plants - ours are fully rooted container grown plants which have had the benefit of having already spent time in the ground, and they still have Herefordshire clay on their roots!

Our People

There are two directors, John and his wife Evelyn - who takes care of Accounts, Wages and much more behind the scenes - and their son and successor, Paul, is the Nursery Manager. This enables decisions to be made very quickly - we don’t have to wait for the 'next board meeting'. Working with us is a group of highly experienced and motivated people who take their jobs seriously; without them, none of this would be possible. Our drivers can assist you in unloading as they are our own people, driving our own vehicles. We currently have 30 staff, including British, Polish, Bulgarian and Ukrainian. Some have returned to us annually since 2006, each one contributing to the local and wider UK economy. Our other full time staff are local people. Yes, our people are good, but our plants are not bad either …

We are a compact business made up of people who are friendly, helpful, and professional, with whom you can easily build a relationship.

Our Services

We generally use our own transport to deliver our stock, meaning that most customers will receive delivery the same week; some may have even experienced our ‘same day’ or ‘Saturday’ service. We want to send you fresh plants for you to sell … remember this is generally in our own transport, driven by our own drivers, who represent John Richards Nurseries. For our valued Customers from whom we are more distantly located we use a specialist delivery contractor - generally White Logistics.

Also available to our Customers is a sample van visit (like a mobile library but a lot more fragrant, and a lot more to look at than you can fit in the boot of a car!). Kate will arrange for one of us to visit your Centre and show you the stock that’s looking good or take your reserve orders, which then guarantees your stock is held for you.

Our Policy

- To offer you a professional service, backed up by efficient aftercare, by people who you know and who care.

- To establish and maintain a long-term working relationship with each of our Customers.

- To look after such, then encourage prospective Customers to 'give us a try'.

- To provide no-nonsense value for money - at the top end of the market.

- To minimise our impact on the environment by the responsible use of natural and man-made resources.

Our stock is not in every garden centre, and, with respect, you will not find our plants in DIY stores or supermarkets. We believe that it doesn’t benefit anyone if two neighbouring garden centres both simply sell the same products.

We always work with a Customer to resolve any problem quickly. We appreciate that sometimes things don’t go as planned, and that we can all make mistakes.

Our Site

We are 850 ft above sea level, just to the west of the Silurian shale foothills of the plutonic Malvern Hills. We are on the Devonian sandstone and have four distinct soil types on our 35 acre site. Local people like to boast "there is no higher ground", in a certain easterly direction, "between these hills and the Ural Mountains"! Yes, when the wind is from the east ... !

We have an on-site cold storage facility which allows us to protect our plants (especially the root and stem base) while inducing hardiness. This also enables us to give our stock (rooted cuttings, liners etc) a ‘winter’ inside - thus ensuring vernalization - when we often don’t have a proper one outside! We set this working and start to fill it around November, and empty it when the last frost has passed. Set to 2 degrees centigrade, this means we can dispatch - even to Northern regions - hardy plants in early Spring.

We have an on-site cold storage facility which allows us to protect our plants (especially the root and stem base) while inducing hardiness. This also enables us to give our stock (rooted cuttings, liners etc) a ‘winter’ inside - thus ensuring vernalization - when we often don’t have a proper one outside! We set this working and start to fill it around November, and empty it when the last frost has passed. Set to 2 degrees centigrade, this means we can dispatch - even to Northern regions - hardy plants in early Spring.

Water - simple H2O!

Life depends on water - which falls from the sky as rain. By growing plants in pots we have taken responsibility to provide for their needs at all times, rain or no rain. Through this rain we are entirely self-sufficient when it comes to the necessary irrigation water. We have our own ‘closed system’ reservoir, which means that everything we take out of this goes back in (minus what is built into the plants and their immediate environment and that incurred by evapotranspiration). Every drop of rain which falls on our site is captured, initially in a 1/3 million gallon ‘lagoon’ which is great for capturing a flash flood, and then through a reed bed (the humble 'Norfolk' reed Phragmyes autralis) before entering the main reservoir which has capacity to hold 5 million gallons - more than enough for us if we had a calendar year without rain. To safeguard aquatic life, including the abundant Great Crested Newt, we have provided a safety gauze at the point of entry of the suction inlets of our extraction pumps. Before use the water is passed through a rapid sand filter, then through Iris beds (the 'flag' Iris pseudo-acoris) to enhance the natural bioflora. A venturi is in place to entrain air, thus enriching the water with oxygen at every opportunity. We buy mains water for washing ourselves and drinking!

Life depends on water - which falls from the sky as rain. By growing plants in pots we have taken responsibility to provide for their needs at all times, rain or no rain. Through this rain we are entirely self-sufficient when it comes to the necessary irrigation water. We have our own ‘closed system’ reservoir, which means that everything we take out of this goes back in (minus what is built into the plants and their immediate environment and that incurred by evapotranspiration). Every drop of rain which falls on our site is captured, initially in a 1/3 million gallon ‘lagoon’ which is great for capturing a flash flood, and then through a reed bed (the humble 'Norfolk' reed Phragmyes autralis) before entering the main reservoir which has capacity to hold 5 million gallons - more than enough for us if we had a calendar year without rain. To safeguard aquatic life, including the abundant Great Crested Newt, we have provided a safety gauze at the point of entry of the suction inlets of our extraction pumps. Before use the water is passed through a rapid sand filter, then through Iris beds (the 'flag' Iris pseudo-acoris) to enhance the natural bioflora. A venturi is in place to entrain air, thus enriching the water with oxygen at every opportunity. We buy mains water for washing ourselves and drinking!

Pot Sterilisation

Due to the 'rotating production' nature of our business we have some important pot sizes which we only use during the production cycle. Without sterilisation we would only have one option: throw them away and replace with new each year, as we cannot risk spreading possible disease. Our sterilizing plant uses only hot water, at 80 degrees C. We stack the pots on specially designed crates which are lowered into the tank of hot water for one hour; this process kills all known pathogens as well as weed seeds. We have been using most of the same pots now for more than the last ten years. "Ah, yes that’s all well and good", I hear you say, "but what happens to all that filthy water afterwards?" That’s a job for those amazing little bacteria in our bio-bed who can’t get enough of this stuff; pretty soon that contaminated water will be pure water vapour.

Due to the 'rotating production' nature of our business we have some important pot sizes which we only use during the production cycle. Without sterilisation we would only have one option: throw them away and replace with new each year, as we cannot risk spreading possible disease. Our sterilizing plant uses only hot water, at 80 degrees C. We stack the pots on specially designed crates which are lowered into the tank of hot water for one hour; this process kills all known pathogens as well as weed seeds. We have been using most of the same pots now for more than the last ten years. "Ah, yes that’s all well and good", I hear you say, "but what happens to all that filthy water afterwards?" That’s a job for those amazing little bacteria in our bio-bed who can’t get enough of this stuff; pretty soon that contaminated water will be pure water vapour.

Waste Recycling

Just like all industries we create a modicum of waste; we all know that - though happily it is diminishing - everything seems to come wrapped in plastic! There is a percentage of our pots which don’t 'make it', so along with all our other plastics we send these to a local recycler (6 miles away) who turns them into imitation timber street furniture, or maybe garden centre display benches. All the packaging in which our growing media is received is baled and returned to the supplier for re-use. We segregate and bale all the cardboard from our general waste, and use the local authority as our waste carrier (not a nationwide giant), thus helping maintain our local economy.

We are one of a very few nurseries in the UK who use a bio-bed. This is a covered pit which contains a mixture of loam, straw and other organic material, in which a very coarse grass grows. Whenever we have any pesticide or sprayer washings, they are emptied into this bed and toxins are naturally removed by bacteria. The liquid portion is removed (as pure water vapour) only by evapotranspiration. There is no drainage outlet from this bed, therefore no pollution. Yes, the 'powers that be' were baffled by this approach as regulations would still allow us (on payment of their fee) to pollute our own land with this waste; this right, of course, we have resigned.

We are one of a very few nurseries in the UK who use a bio-bed. This is a covered pit which contains a mixture of loam, straw and other organic material, in which a very coarse grass grows. Whenever we have any pesticide or sprayer washings, they are emptied into this bed and toxins are naturally removed by bacteria. The liquid portion is removed (as pure water vapour) only by evapotranspiration. There is no drainage outlet from this bed, therefore no pollution. Yes, the 'powers that be' were baffled by this approach as regulations would still allow us (on payment of their fee) to pollute our own land with this waste; this right, of course, we have resigned.

Sustainable living

In February 2016 we finished work on the Nursery Manager’s house. The local authority was very understanding of the need for a house, but also mindful of the fact that we are located within an AONB (Area of Outstanding Natural Beauty). The brief to the architect was to design a low environmental impact house which was sustainable and low maintenance. All the external surfaces are indeed very low maintenance: either aluminium or untreated Western Red Cedar. All liquid effluent, either sewage or rainwater, is collected, passed through reed beds and reused. The toilets all use recycled water to flush. The result is an air-tight, well insulated and bright house which requires minimal energy to heat - a ground-sourced heat exchanger pre-heats or pre-cools (dependent on the time of year) the fresh air as it is drawn underground into the house.

Growing Media

It has never been our policy to buy this as an off-the-shelf proprietary product; rather we try to understand what is going on in the root-zone and to freshly mix on-site using bulk ingredients and varying proportions of nutrients, pH adjusters etc. In previous years the bulk ingredients have been 80% peat and 20% wood fibre.

We are fortunate in having on our site a large supply of loam. This began as top-soil removed prior to constructing our large reservoir and container beds. On this we establish mown grass, we rotavate the top 25mm and push into windrows for Summer maturation before taking under cover for shredding and heat-pasteurization.

To try and gain an understanding of the properties and performance of alternative materials, extensive in-house trials are underway to identify suitable materials for the complete replacement of peat. We started out in early 2023 with 17 formulae for ‘general stock’ i.e. most trees and shrubs: 3 for Conifers and 14 for Ericaceous. Needless to say we are getting many surprises! Key characteristics we are tracking are water-holding, air-filled porosity, nutrient retention, pH stability, aeration, density, capilliarity, resistance to ‘slumping’; then practically, ‘flowability’, ‘cohesiveness’, over-wintering success, flower-bud initiation propensity and friendliness to beneficial bio-flora. Some of these we will not know until next Spring. At the same time, we are calculating the aggregate road/rail/sea miles incurred by the ingredients of each formula. To the right is an example of a completely peat-free wall shrub.

To try and gain an understanding of the properties and performance of alternative materials, extensive in-house trials are underway to identify suitable materials for the complete replacement of peat. We started out in early 2023 with 17 formulae for ‘general stock’ i.e. most trees and shrubs: 3 for Conifers and 14 for Ericaceous. Needless to say we are getting many surprises! Key characteristics we are tracking are water-holding, air-filled porosity, nutrient retention, pH stability, aeration, density, capilliarity, resistance to ‘slumping’; then practically, ‘flowability’, ‘cohesiveness’, over-wintering success, flower-bud initiation propensity and friendliness to beneficial bio-flora. Some of these we will not know until next Spring. At the same time, we are calculating the aggregate road/rail/sea miles incurred by the ingredients of each formula. To the right is an example of a completely peat-free wall shrub.

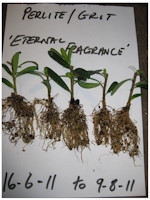

Positively, since January 2023 all our rooting media for cuttings has been 100% peat-free. We do have some experience as we first tried this in 2011!

See our Growing Media page for further details.

Electricity

We have invested significantly in energy-efficient motors, lighting, etc, and, yes, we do have some PV solar capture panels. These are on our coldstore roof and give the additional benefit of trapping solar heat before it reaches the building, thus (by reducing the cooling energy required) giving a double saving. We believe this goes some significant way to offsetting the CO2 etc released in the Far East when these were manufactured.